Opti-Corrugated

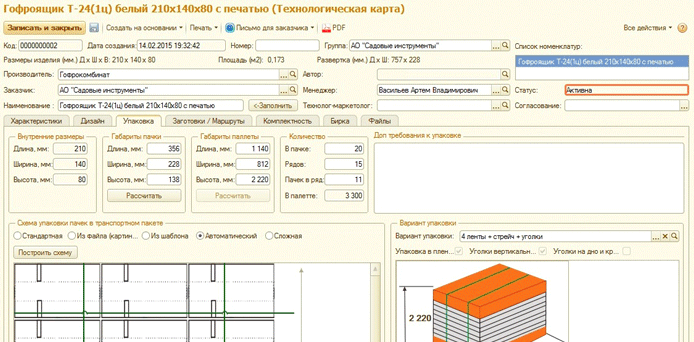

The main source of savings: reducing the raw materials losses in cutting and post-processing, optimizing the use of materials, reducing in-process inventory, optimizing the stock in warehouses and better planning of shipments.

Using the system when planning corrugated board production can give the company a significant economic effect, primarily by reducing the cost of raw materials by 1..2%. Considering that the share of raw materials costs (cardboard and paper) in finished goods reaches 70..80%, the use of the system can reduce the production costs by 2..4%.

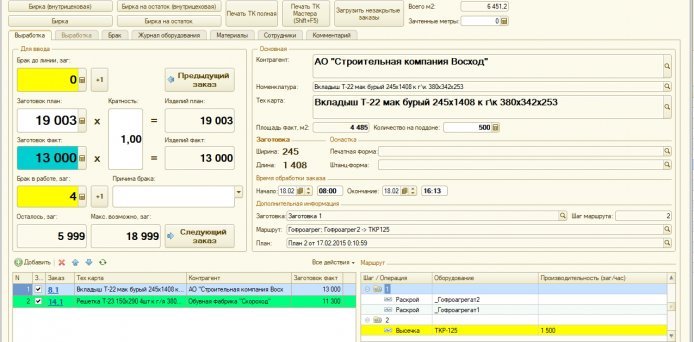

The system uses advanced optimization modules for scheduling the operation of corrugators and processing lines, which allow reducing the time of production and shipment of finished goods.

Users get immediate access to the production process, reports on execution of technological operations, and other process information.

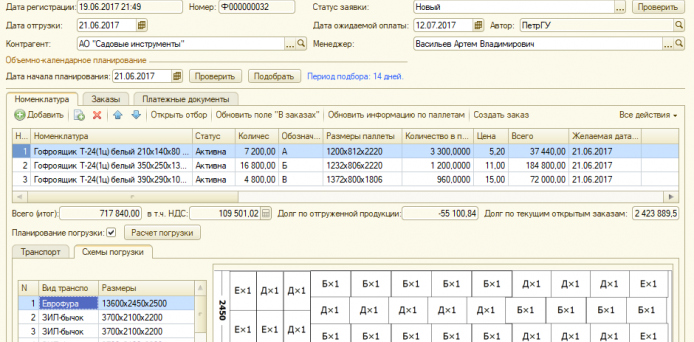

The pre-planning module allows calculating actual shipping dates based on the current production plan, equipment operation schedule, availability of material resources and additional stamp.

The System can be used as a stand-alone product, as a Web-interface, or integrated to other information systems supporting SOA (Service Oriented Architecture)

Use of the "cloud" service enables more flexible management of the system functions: when the production conditions change, the company can choose a different set of functions that better meet the new conditions.

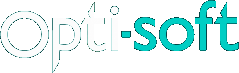

- pre-production engineers;

- sales managers;

- shift masters of processing lines;

- shift masters of corrugator lines;

- warehouse services;

- economic services;

- management of the enterprise and divisions.

Reducing the manufactured goods costs by 5..10%

Reducing the manufactured goods costs by 5..10%  Reducing raw materials losses by 1.5..4%

Reducing raw materials losses by 1.5..4%  Reducing warehouse volumes by 10%

Reducing warehouse volumes by 10%  Increasing the equipment uptime by 3..4%

Increasing the equipment uptime by 3..4%  Reducing unproductive equipment downtime by 5..8%

Reducing unproductive equipment downtime by 5..8%  "Just-in-time" production of goods

"Just-in-time" production of goods